Specifications

Composeal Gray 40 Mil PVC complies with the standards of ICC-ES for the USA and Canada (report PMG-1459) and and NES (PCR SP 102). Composeal Gray has separate municipal approval where required, City of Los Angeles (RR#4398), City of Philadelphia (40 mil), Metropolitan Dade County, Florida and The Commonwealth of Massachusetts. Approval is no longer required in New York City for concealed PVC waterproof membrane.

Composeal Gray 40 Mil PVC also complies with the Corps of Engineers specs for PVC shower pan material (para 5.8.3.2 15 p1-18) and meets the requirements of FHA Publication 4900.1.

Composeal Gray 40 Mil PVC meets and surpasses the engineering requirements of the American Society for Testing and Materials (ASTM). ASTM D4551 is the test standard established for PVC membranes used for Shower Pans.

- Flexible Waterproofing for Floors & Walls

- Custom Tiled Showers, Baths, Fountains, Roof Decks, Terraces, Exterior Stairs & Walkways

- Easily Formed to Fit Any Dimensions or Drain Location

- Durable and Long Lasting

- Ideal for New Construction & Renovations

- Economically Priced

- 50% Recycled Content

- 40 mil Thickness

- Available in 5 & 6 foot widths

- Available in 50 & 100 foot rolls

- Meets and surpasses ASTM D4551 for PVC flexible waterproofing membrane

- Made in the USA

Installation Requirements

Installation Instructions

- Before placing pan, ensure the sub-floor is sloped toward drain ¼″ per foot using cement mortar if necessary, and is free of loose objects or projections such as nail heads or gravel.

- Make turn-up along walls not less than 3″ above curb line, allowing sufficient material to fasten to outside face of curb and out onto floor a few inches away from shower. If there is no curb in the shower, materials should be fastened 6″ above the floor.

- Notch wood studs to ½″ to the height of the pan to allow Composeal to be flush with face of the studs. For metal studs, use furring strips (¼″ to ½″) above the top of the pan.

- Fasten 3″ or higher above the top of curb. Use flathead roofing nails or staples on wood studs. Use drywall screws and washers on metal studs. DO NOT penetrate the membrane anywhere below the 3″ mark to maintain waterproof integrity of the pan.

- Fold Corners outside pan. Allow for plumb surface by turning corner folds out of the way between studs. Notch studs or use furring strips mentioned above to maintain a flush surface. DO NOT cut pan corners.

- Use bolt-down clamping-ring type drain with weep-holes. Set so sub-drain lip is flush with subfloor. Trim opening for drain exactly to the size of drain opening – NOT out to bolt holes. Pierce membrane at the bolt holes with a nail or similar to accommodate bolts with a tight fit. Use Compotite Elastiseal Pro or a 100% mold/mildew resistant silicone to bond the pan and sub-drain.

- Plug sub-drain and fill with water, letting it stand for 24 hours to ensure clamping ring is tight and pan is watertight and undamaged. Bolt clamping ring firmly. Place a small amount of pea gravel or other porous material at weep holes so they remain clear when setting bed is poured.

Related Products for Installation

SEAM WELDING

Composeal Gray sheets can be welded together to create a perfect waterproof bond with instant contact strength using Compotite’s Weld-Tite Flexible Vinyl Cement. Use only Compotite approved PVC cement. Lay sheets with an overlap of two inches with upper lap edge toward the direction of watershed. Fold back top edge and apply Weld-Tite Flexible Vinyl Cement to both surfaces. Once the surfaces have become slightly tacky, place together and press or roll to form a tight bond. Always verify complete adhesion of the layers.

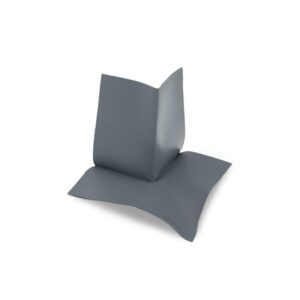

CORNERS & CURB PROTECTORS

Composeal Gray 40 Mil PVC corners are multi-purpose, preformed corners/curb protectors that reinforce waterproofing at all corners and curbs. Use Weld-Tite Flexible Vinyl Cement to weld corners to PVC sheet.

SEALANT

Compotite Elastiseal Pro is used to bond Composeal Gray 40 mil PVC to the sub-drain assembly. DO NOT use Elastiseal Pro to weld PVC sheets together.